Specification:

Rated capacity:2000t/h~12000t/h

Feeding material granularity:

0~2000mm

Discharging material granularity:

0~450mm

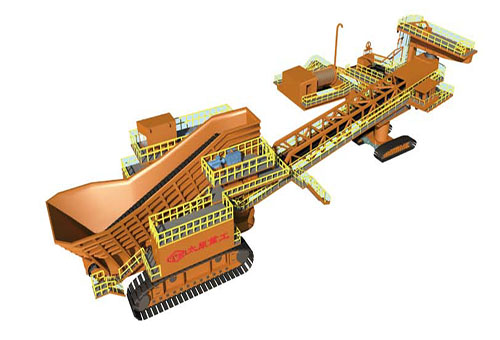

Mobile crushing station is an extra-heavy crushing equipment developed by our company for crushing overburden material or gross coal in open-pit mine with annual output over 10 million tons. This crushing station is applicable to mining technology of single bucket excavator-mobile crushing station-cable hopper car-belt conveyor. In the condition of no temporary brace the crushing station, with good receiving stability and maneuverability, can receive material directly from hydraulic or electric shovel and is able to move flexibly.

Specification:

Rated capacity:2000t/h~12000t/h

Feeding material granularity:

0~2000mm

Discharging material granularity:

0~450mm

Tel.: +86-351-6367015,15383613301

Email: dongfan@tz.com.cn

Application

Self-mobile crushing station is designed for primary crush of overburden or gross coal in large open-pit mine with output above ten millions and is applicable to the mining processing of single bucket excavator-self mobile crushing station-belt conveyor. Double rollers mobile crushing station mainly consists of mobile crusher, one-piece connecting bridge (or loader) and cable hopper car and etc. When excavator working with Self-mobile crushing station, its average swing angle is less than 90° and thus to improve the efficiency.

Features

Parameters

Rated capacity (t/h) |

Receiving grain size (mm) |

Discharging grain size (mm) |

Volume of receiving hopper (m3) |

Model of the crusher |

Motor Power (KW) |

Center distance of feeder (mm) |

Power of track device (kW) |

Ground pressure (KPa) |

Gradability (°) |

9000 |

0~2000 |

0~400 |

225 |

16/350CCTD |

2×630 |

20250 |

2×425 |

<240 |

10 |

7500 |

0~2000 |

0~400 |

165 |

13/300CCTD |

2×480 |

20250 |

2×425 |

<240 |

10 |

4500 |

0~2000 |

0~400 |

105 |

11/300CCTD |

2×350 |

20250 |

2×425 |

<240 |

10 |

3000 |

0~1500 |

0~300 |

105 |

11/220CHD |

355 |

20250 |

2×425 |

<240 |

10 |

![]() Telephone:+86-351-6366223

Telephone:+86-351-6366223

![]() Fax:+86-351-6360994

Fax:+86-351-6360994

![]() E-mail:info@tz.com.cn

E-mail:info@tz.com.cn

Mobile version

Copyright © 1998-2019 Taiyuan Heavy Industry Co., Ltd. 晋ICP备05004298 晋公网安备 14010902000286号