Main parameters:

Working diameter: Φ400mm~1300mm

Length diameter ratio: 0.6~0.9

TYHI have been designing and manufacturing various Hydrodynamic and Hydrostatic-hydrodynamic oil film bearings, which meet with the requirements of heavy loading, high speed and rolling precision for the 650mm, 1220mm, 1420mm, 1780mm, 2030mm cold rolling mills and so on.

Main parameters:

Working diameter: Φ400mm~1300mm

Length diameter ratio: 0.6~0.9

Tel.: +86-351-6362448,13753106425

Email: lijunlin@tz.com.cn

Application

Our oil film bearings are installed in back-up roll assembly (or work roll assembly), to bear the rolling pressure and ensure low-energy-consumption performance of the rolls.

Features

Structure

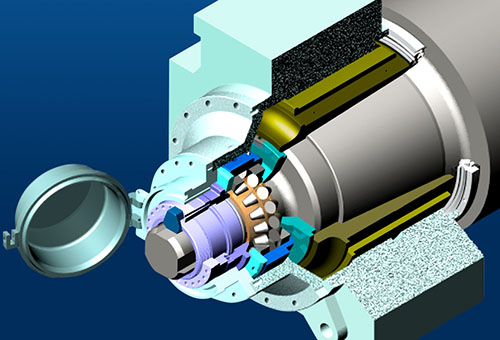

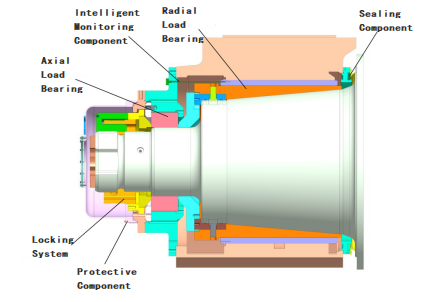

The oil film bearing can be divided into two types, Hydrodynamic type and Hydrostatic-hydrodynamic type, which is selected according to the specific working condition of the mill. A set of oil film bearing mainly consists of radial loadtaking system, axial loadtaking system, sealing system, locking system, protection system and monitoring system.

In the radial loadtaking system, the sleeves are of two different types: keyless and keyless & thin wall; hydrostatic-hydrodynamic bushings are of three types: single oil cavity, double oil cavity and four oil cavity; Axial loadtaking system have two different structures: single thrust and double thrust; there are two different types of seals in sealing system: JF seal and ACS seal; there are three different types of locking system: mechanical locking, hydraulic locking and mobile hydraulic locking. Customers are free to make their decision of combination of above various types in accordance with their conditions.

Reference

The reference of domestic cold rolling mill oil film bearings

No. |

Customer |

Mill Type |

Specification |

Mill designer |

1 |

Baoshan Iron and Steel Co. Ltd |

2030 Cold rolling mill |

ZYC1065-72J |

MHI |

2 |

Angang Steel Co. Ltd |

1780 Cold rolling mill |

ZYC1100-75WJJ |

MHI |

3 |

Wuhan Iron and Steel Co. Ltd |

1700 Cold rolling mill |

ZYC1065-72J |

|

4 |

Benxi Iron undefinedamp; Steel (Group) Co. Ltd |

1700 Cold rolling mill |

ZYC825-90J |

|

5 |

Panzhihua Iron and Steel Group Xichang steel vanadium Co. Ltd |

1420 Cold rolling mill |

ZYC750-90J |

|

6 |

Baoshan Iron and Steel Co. Ltd |

1420 Cold rolling mill |

ZYC785-75WJJ |

|

7 |

Xinjiang Ba Yi Iron undefinedamp; Steel Co. Ltd |

1420 Cold rolling mill |

ZYC825-84WJJ |

|

8 |

Angang Steel Co. Ltd |

1200 Cold rolling mill |

ZYC785-75WJJ |

|

9 |

Tangshan hengtong thin plate cold rolling Co. Ltd |

1200 Cold rolling mill |

ZYC825-84WJJ |

|

10 |

Wuxi Xindazhong Steel Sheet Co. Ltd |

850 Cold rolling mill |

ZYC650-75WJ |

|

11 |

Wuxi Xindazhong Steel Sheet Co. Ltd |

650 Cold rolling mill |

ZYC413-75WJ |

The export reference of cold rolling mill oil film bearings

No. |

Customer |

Mill Type |

Specification |

Mill designer |

1 |

Arcelormittal steel Co. Ltd, South Africa |

1700 Cold rolling mill |

54"-75 |

|

2 |

Arcelormittal steel Co. Ltd, Kazakhstan |

1700 Cold rolling mill |

Φ1120×840 |

|

3 |

Zaporozhstal steel Co. Ltd, Ukriane |

1680 Cold rolling mill |

Φ900×670 |

|

4 |

Zaporozhstal steel Co. Ltd, Ukriane |

1680 Reversible mill |

Φ1000×750 |

|

5 |

Arcelormittal steel Co. Ltd, Kazakhstan |

1500 Cold rolling mill |

Φ1000×750 |

|

6 |

Synn Industral Co. Ltd, Taiwan |

1300 Cold rolling mill |

44"-90 |

|

7 |

Dai Thien Loc Steel Co. Ltd, Vietnam |

1250 Cold rolling mill |

42"-90 |

|

8 |

AHMSA Steel Co. Ltd, Mexico |

1250 Cold rolling mill |

42"-67 |

Awards

1. TZ oil film bearing series ZYC160-1800 are awarded gold prize as National Quality Product.

2. TZ oil film bearing is awarded with "China famous brand product in September 2005.

3. The Industrial Standard of Oil Film Bearing is awarded with Second Class Prize by the Ministry of Machinery Building Industry.

4. TZ oil film bearing series ZYC1300 is awarded with Third Class Prize by the Ministry of Machinery Building in scientific and technology progress.

5. TZ ZYC500 Hydrostatic-Hydrodynamic Oil Film Bearing is awarded with Second Class Prize by Shanxi Provincial Government for scientific and technology progress.

6. TZ ZY900 bearings are awarded with First Class Prize by Taiyuan Municipal Government for scientific and technology progress.

![]() Telephone:+86-351-6366223

Telephone:+86-351-6366223

![]() Fax:+86-351-6360994

Fax:+86-351-6360994

![]() E-mail:info@tz.com.cn

E-mail:info@tz.com.cn

Mobile version

Copyright © 1998-2019 Taiyuan Heavy Industry Co., Ltd. 晋ICP备05004298 晋公网安备 14010902000286号